Washer Compactor

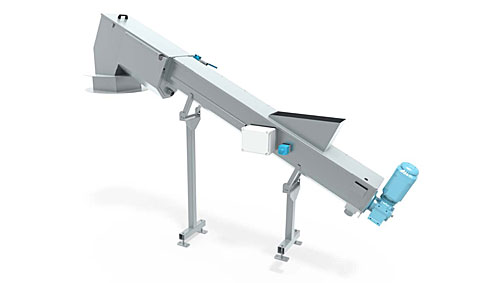

Compactec is a highly efficient washer/compactor system that conveys, cleans, dewaters, and compresses debris. The shaftless screw mechanism transports the screened debris while the spray bar system returns organic material back into the system.

The compression box effectively reduces the volume of debris, minimizing transportation costs. This versatile system can easily retrofit any kind of bar screen equipment, making it a valuable addition to any wastewater treatment facility.

• Sturdy.

• Reliable.

• Economical.

• Fast return on investment.

• Low and economical maintenance.

• Low energy consumption.

Compactec will help optimizing the reduction of solid waste while sending organic back to the treatment.

Description

OPERATING MODE

The captured solids are conveyed by a shaftless auger into the washing zone where they are cleaned and dewatered. The debris are then compressed and discharged, reducing its volume and making it more cost-effective to transport and dispose of.

Additionally, the spray bar system allows organic material to be sent back to the system, reducing waste and operating costs. Compactec can be easily retrofitted to any existing bar screen equipment.

Features & Benefits

1. Mechanism

The transport mechanism of the Compactec system utilizes a shaftless auger constructed from alloy steel and coated with protective polyurethane paint. The transport tube, with a minimum width of 7″ and a thickness of ¼”, is made of either 304L or 316L stainless steel. In addition, the transport tube is covered with high-density polyethylene (HDPE) liner, which helps to ensure the system’s durability and longevity.

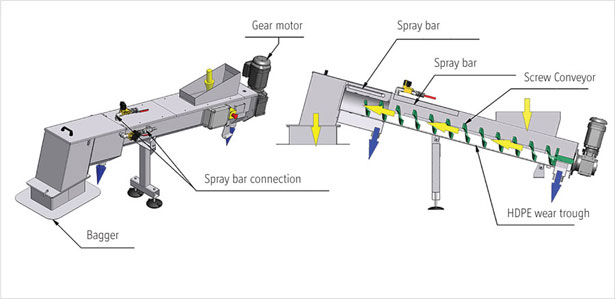

2. Spray Bar System, Maximum Organics Back In The Process

To enhance the removal of organic material from debris and reintroduce it back into the wastewater process, the Spray Bar System features two spray bars equipped with a combined 4” drain. One spray bar is located on the conveyor, while the other is situated to spray into the compression box. This dual configuration maximizes the amount of organic material that can be effectively captured and returned to the WTP process.

3. Volume Reduction

In the Compactec system, the screw applies pressure to the debris, pushing it against the variable-pressure lid. As this happens, the screened material is effectively dewatered and compressed. To meet landfill regulations and Paint Filter Test requirements, the pressure of the lid can be easily adjusted as needed.

4. Odor Control

All Aqualitec bar screens are completely enclosed, and Compactec’s bagger system further controls odor.

Design Guidelines

• Capacity: 0 to 9,500 gallon/day (0 to 1,5m3/h) of compacted waste

• Water: Non potable but clean water

• Water: Between 2 and 20 gal per hour

• Water pressure: min 72psi

• Installation angle: 0° to 25°

• 304 or 316 Stainless Steel

• Drain connection 4’’

• Absorbed power: ¾hp (0.56KW)

• Voltage: custom to site availability – 3φ required

Applications

• Headworks

Contact Us

Looking for a Screening Solution?

For any questions about our wastewater treatment solutions, please fill out the contact form below and our team of experts will get back to you shortly.