Spiral Screen

all-in-one solution

Spiraltec is a cylindrical screw screen that offers a comprehensive solution for collecting, conveying, dewatering, and compressing wastewater solids.

Spiraltec is an ideal option for applications with limited space or shallow channels, offering a practical solution that can be easily integrated into any wastewater treatment process.

• Sturdy.

• Reliable.

• Economical.

• Fast return on investment.

• Low, economical maintenance.

• Low energy consumption.

Spiraltec will help you save money while improving process and working conditions.

Description

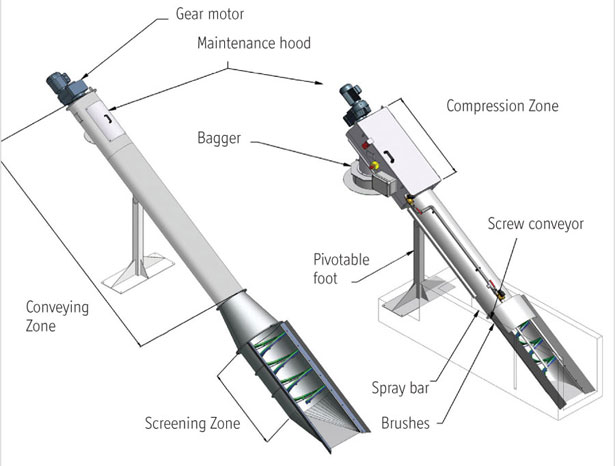

OPERATING MODE

Spiraltec is specifically designed to remove debris from wastewater, utilizing an inclination of 35° from horizontal for optimal performance. The system features a perforated screen that effectively retains debris during operation.

Once the debris are captured, a spiral screw conveys, dewaters, compacts, and discharges it upward and into a dumpster, ensuring efficient and reliable processing of the collected material.

Features & Benefits

1. All-In-One Solution

A stationary perforated plate basket located at the bottom of Spiraltec retains all screened debris. A spiral screw then conveys, dewaters, compacts, and discharges the screened material into a dumpster.

2. Brushes Easy To Replace

Spiraltec’s efficient cleaning and particle transport system relies on brushes bolted onto the shaftless spiral.

To ensure hassle-free maintenance, the brushes are divided into one-foot sections. This design allows for easy replacement of individual brush sections, minimizing downtime and reducing the need for specialized tools or expertise.

3. Tiltable

Spiraltec is designed for easy maintenance and servicing. In the event of maintenance needs, the unit can pivot on its feet, allowing convenient access to the interior for inspection, cleaning, or repairs. This feature reduces downtime and streamlines the maintenance process, resulting in more efficient operations and cost savings over time.

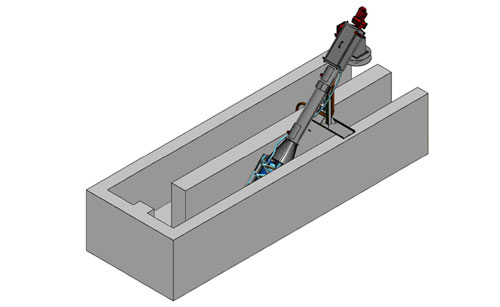

4. In-Tank Option

Spiraltec can be built in-tank, making it compatible with virtually any wastewater structure. This feature enables easy retrofitting of existing systems and reduces the need for costly modifications. In particular, an in-tank Spiraltec installation is well-suited for septage receiving station applications, providing efficient and reliable solids separation in a compact footprint.

5. Minimal Maintenance

Weekly maintenance involves visually inspecting the drum and the nozzles on the spray bars. When necessary, the nozzles can be easily removed for cleaning or replacement.

Design Guidelines

• Flow: up to 6mgd

• Depth: 2’ to 6’

• Width: 8’’ to 28’’

• Perforated plate from 2mm (5/64’’)

• Installation angle: 35°

• In channel or In tank

• 304 or 316 Stainless Steel

• Shaftless or shafted

• Touch Screen Control Panel

• Absorbed power: ½hp (0.37KW)

• Voltage: custom to site availability – 3φ required

Applications

• Headworks

Contact us

Looking for a Screening Solution?

For any questions about our wastewater treatment solutions, please fill out the contact form below and our team of experts will get back to you shortly.